Sensor Methods

Electrochemical

Electrochemical sensors

Metal Oxide

Metal Oxide gas sensors work by measuring the resistance change of the metal oxide due to the adsorption of gases. Composed of a tin dioxide semiconductor sensor on an insulating ceramic base, it detects carbon monoxide by measuring the resistance of the tin dioxide, which decreases in the presence of CO. For the sensor to operate, the element must be heated to approximately 400 °C, which effectively purifies the oxide from contaminants. When not actively sensing, metal oxide sensors often have a low power mode where they can be he heated to a fraction of the temperature, keeping the stabilization. Sensors left unpowered for long periods of time require days of aging time to become stable again. Highly sensitive to heat, gasses, vapours/ humidity with a lifetime of about 5 years. The drive circuitry is very simple, 5V to power the heater, 5V in series with a load resistor across the sensing terminals. The voltage drop across the load resistor is proportional to the resistance of the tin dioxide. The output of this device is on an exponential decay scale making it more difficult to read measurements than a linear response.

A more recent development of this metal oxide sensors is the use of MEMS (micro-electromechanical system) technologies. Allowing implementation of heating and sensing elements by thin film fabrication, this reduces power consumption to 10s of mWs rather than close to 1W and overall reduces the package size.

https://www.fierceelectronics.com/components/metal-oxide-gas-sensing-material-and-mems-process

- $10.15

- Sensitive to both CO and CH4 (methane)

- 10-500ppm CO, 300-10000ppm CH4

- Heater model so draws max 900mW

- Readings through resistance

- NOT UL CERTIFIED

- $31.24

- 15 year expected life

- Low cross sensitivitiy

- 15 second response time

- Low profile

- I could make an adapter board that fits on the I2C headers the CO2 module uses

- SMT or TH version

- Must be hand assembled

- passes 5000ppm overload

- Sensitive to moisture

- 0 - 1000ppm

- <100ppb resolution

- Sensitive to conditions - Humidity

- 12 month shelf life

- $62.78

- 0-1000ppm

- .1ppm resolution

-

5 year lifetime

- Low cross sensitivitiy

- 10-30s response time

- 12 month shelf life

- $15.30

- SMT

- CO / NO2 sensor dual package

- Cross sensitive to H2, CH4, NH3, C2H5OH

- Header module -> ~100mW

- I2C / UART Connection

- 32x37x31mm

- 2 year working life

Research Items

- Connection methods

- Digitial

- Analog

- Mounting

- CO dispersal

- Must fit in deep backplate

- Power draws

- Analogue

- SS3 needs low power

- 30mA at 5V max

- What are ranges of these gasses

- Check competitive analysis > power consumption

- ACI

- Standards -> UL

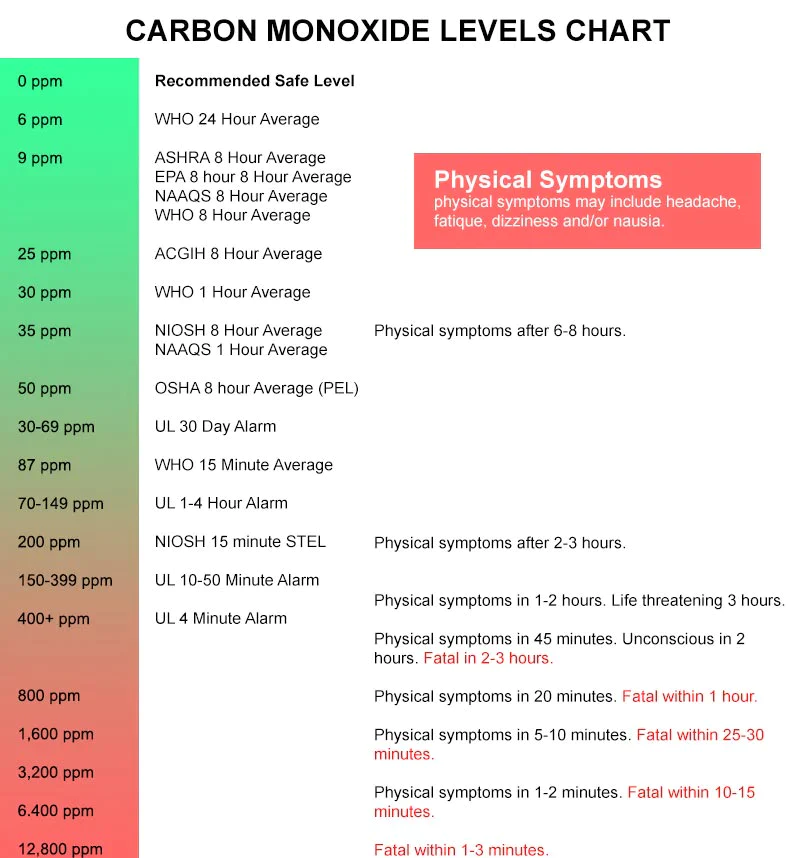

- Same chart

Acceptable levels

WHO Suggestions

WHO Suggestions

- 9-10 ppm for no more than 8 hours

- 25-35 ppm for no more than 1 hour

- 90-100 ppm for no more than 15 minutes